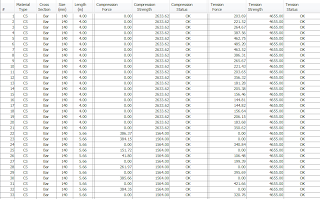

At the beginning of my design, I saw that creating an arc-type truss above the roadbed would prove to be the most sufficient and give the bridge a very powerful basis of construction. Once the outer shell was complete I began filling the bridge design with small, strong triangles in order to reinforce the already strong structure. After a few tweaks and test runs, I saw my compression in the top portion was too much so I added a truss under the bridge with basic large triangles and this gave my bridge the strength it needed to get to .41 and under in compression and tension across the design. As is, the bridge costs $754,714.75. Given a little more time over the next week or so, I believe I can get under the 700K threshold and still have a very sustainable bridge design. Upon completion of my design I did find the arc design to be the strongest while supported with small and medium sized triangles. Shown below are three photos of my bridge design, the compression/tension/truck and the Load test results in which I am quite pleased with.

No comments:

Post a Comment